|

30ML Panasonic Patch Red Rubber

Collect

NO PCB Adhesives

Properties Uncured

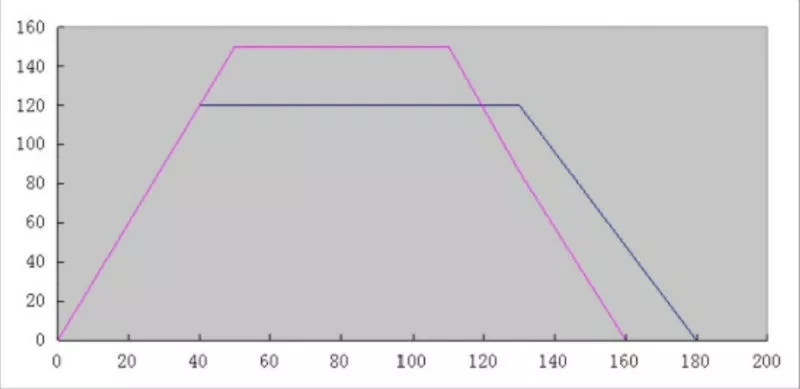

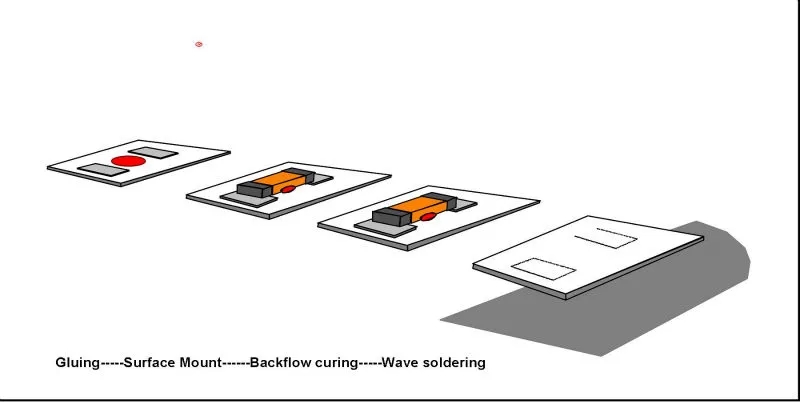

Curing Condition Recommended 90-120s at 120°C. 60-90s at 150°C The product will obtain to higher bonding strength when higher curing temperature and longer cured time . the figure curve is the recommended curing temperature and heating rate,Underthe corresponding temperature ,components need the time when they achieve good bonding strength. Users can set the curing furnace’s temperature parameters according to the solidified characteristic curve of the glue and the heat efficiency of the Reflow Ovens Performance After Cured (Cured for 30min@150°C)

Physical Property

Direction For Use The product should be recovered to room temperature before use, don't open the aluminum foil package before recovered to room temperature(the recovering time of 300ml packaging at least 2-4 hours). The product should be used at 25°C , The glue viscosity will decline under the higher temperature, which influence printing effect; High humidity can increase the glue of moisture absorption which shorten the opening hours of the glue and influence the glue bonding strength. This product opening time is 48 hours at 25 °C,55% Rh. Suggest to print at the speed of 20-150 mm/s; Drawknife pressure is 3-4 N/cm (Afer scraping, sheet should be clean, and avoid producing wire drawing); the deviating speed from the sheet is 0.1-3.0 mm/s. Not cured adhesive which is stick on line wires can be erased with acetone or propylene alcohol ethers. Please seal and chill when not using up the glue.

|